Expansion chambers for an airplane!?

August 4, 2014

Colomban Cri-Cri, Expansion Chambers, Machine Tools, Metal Fabrication, Technical Article, Welding

When I got a call to make a set of expansion chambers for “The world’s smallest manned twin engine airplane” I just could not resist!

The Colomban Cri-cri (or Cricket) was designed in the early 1970’s by Michel Colomban. Since then many renditions have been built. Most Cri-cri aircraft are powered by two single-cylinder 2-stroke engines making 9-15 HP each. However this Cri-cri is special in that it has two twin-cylinder 2-strokes as the power plants!

Here is 2 minute documentary on the Colomban Cri-cri…

The idea behind the expansion chambers for the Cri-cri will be to make the engines more efficient to increase fuel economy and fly time, rather than to increase the power potential as is the usual goal on a motorcycle.

It is well known that a 2 stroke engine is the most efficient when it is “on the pipe” and in harmony with those important pressure waves.

The pressure waves in the pipe are actually timed by the pipe’s tuned length to do their job of plugging or “valving” the exhaust port as it closes. This prevents the escape of fresh fuel-air charge that is coming into the cylinder at the same time. The pressure waves in the pipe also create a vacuum at the exhaust port as it opens to help draw exhaust out of the cylinder and fresh fuel-air charge into the cylinder.

“Operation of two-stroke” by Agster – Licensed under Creative Commons Attribution-Share Alike

“Operation of two-stroke” by Agster – Licensed under Creative Commons Attribution-Share Alike

An expansion chamber is a complex resonate instrument that I like to think of as a 2 stroke’s “valves,” since it functions similar to a 4 stroke cam shaft in the sense that it controls flow into and out of the cylinder at precise times in the engine’s cycle. Because the valving effect of an expansion chamber is based on resonance or vibrational energy it only occurs at the resonate frequency of the chamber; for example, how a tuning fork only rings at a certain tone or vibration, this it its resonate frequency. It is at this resonate frequency that the pipe has its greatest energy producing potential, and this only occurs at the RPM who’s vibration or frequency matches that of the pipe.

I am working on writing a technical article explaining how pipes work in great detail and their design. But for now, to make a long story short: airplane engines run at a very constant RPM compared to motorcycle engines, so they are perfect candidates to “stay on the pipe” and gain constant efficiency enhancement from the expansion chamber! This allows one to run a pipe design with a high efficiency enhancing potential at a narrow RPM range. In contrast, pipes designed for motorcycles sacrifice the best power producing potential in order to produce power over a wider RPM range and in turn keep the bike rideable in the wide range of conditions it has to ride through.

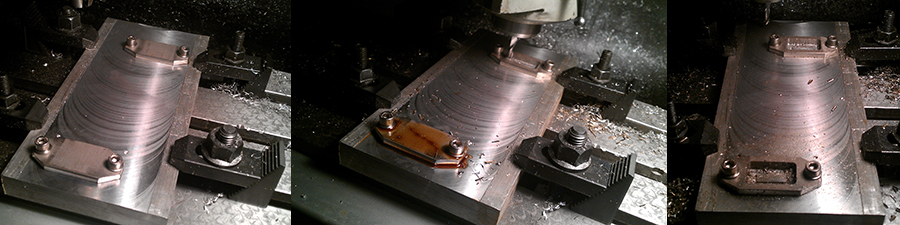

The fabrication process for the expansion chambers starts this time by machining the stainless steel flanges that will attach to the engine’s exhaust ports. The aluminum fixture used here holds the flanges and their mounting bolt holes in the exact position that they will be in when attached to the engine. This ensures that the ports will be cut to align correctly with the engine’s exhaust ports.

Next, head pipes are cut from stainless mandrel bends. They are carefully fit together with seamless joints for welding. Note how the same fixture that was used to machine the mounting flanges doubles as an alignment fixture for welding.

Here are a few photos of the headers after welding. They are a 2-into-1 yoke design similar to chambers used on multi-cylinder snowmobile and watercraft engines. Note the slip fit sleeves in the center photo, these will be used to attach the chambers with retaining springs.

Here are the finished chambers with integral silencers like those used on my Denco replicas, and Kawasaki A7 Bombers,

A few shots of the owner fitting the pipes to his aircraft.

And some final product shots 🙂